A Vital Component of Internal Combustion Engines

The crankcase, recognised in German as “Kurbelgehäuse,” is a essential factor of inner combustion engines, serving because the housing for the crankshaft and different associated parts. Its layout and functionality are essential for engine performance, efficiency, and durability.

Structure and Design

The crankcase is commonly produced from strong materials together with cast iron or aluminum alloys to face up to the mechanical stresses and thermal variations encountered all through engine operation. Its primary feature is to encase the crankshaft, offering guide and preserving alignment with other engine components. Additionally, the crankcase serves as a reservoir for engine oil, facilitating lubrication of shifting elements and assisting in warmth dissipation.

Functions of the Crankcase

- Support and Alignment: The crankcase ensures precise alignment of the crankshaft and related additives, that is essential for easy engine operation and minimizing put on.

- Lubrication: Acting as an oil sump, the crankcase shops engine oil and consists of channels that distribute lubricant to numerous engine components, reducing friction and preventing overheating.

- Protection: It shields internal additives from outside contaminants inclusive of dirt and particles, thereby enhancing engine sturdiness.

- Structural Integrity: The crankcase contributes to the general tension of the engine assembly, supporting to hose down vibrations and decrease noise at some stage in operation.

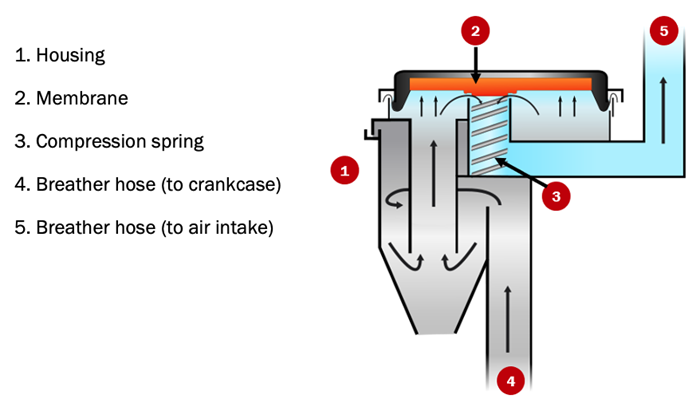

Crankcase Ventilation

Effective crankcase ventilation is important for retaining engine health. During combustion, gases can leak past the piston jewelry into the crankcase, leading to multiplied stress and capability oil contamination. A air flow device, frequently comprising a Positive Crankcase Ventilation (PCV) valve, allows those gases to be redirected again into the combustion chamber for re-burning, thereby reducing emissions and preventing stress buildup.

Common Issues and Maintenance

Over time, the crankcase can expand problems including oil leaks, frequently because of degraded seals or gaskets. Regular maintenance, consisting of timely oil changes and inspections, is important to make certain the crankcase stays in most advantageous condition. Addressing leaks promptly and making sure the ventilation system capabilities efficiently can prevent more excessive engine troubles.

Advancements in Crankcase Technology

Modern engines have visible substantial improvements in crankcase layout and materials. The use of lightweight alloys and precision engineering has led to advanced engine performance and overall performance. Additionally, more advantageous ventilation structures have been developed to meet stringent environmental regulations through successfully lowering dangerous emissions.

Conclusion

The crankcase (Kurbelgehäuse) is a essential component that performs multiple roles in the functionality of an inner combustion engine. Understanding its layout, features, and the significance of proper renovation can aid in making sure engine durability and optimal overall performance. As car era keeps to evolve, the crankcase stays a crucial element in engine structure, adapting to fulfill the needs of modern-day engineering and environmental standards.