Technology, Innovation, and Future Trends in the Automotive Industry

The camshaft, referred to as “Nockenwelle” in German, is a pivotal element in internal combustion engines, orchestrating the ideal timing of valve operations to make certain top-rated engine performance. This article delves into the intricacies of camshaft design, function, and improvements, with a focal point on the German automotive enterprise.

1. Introduction to Camshafts (Nockenwellen)

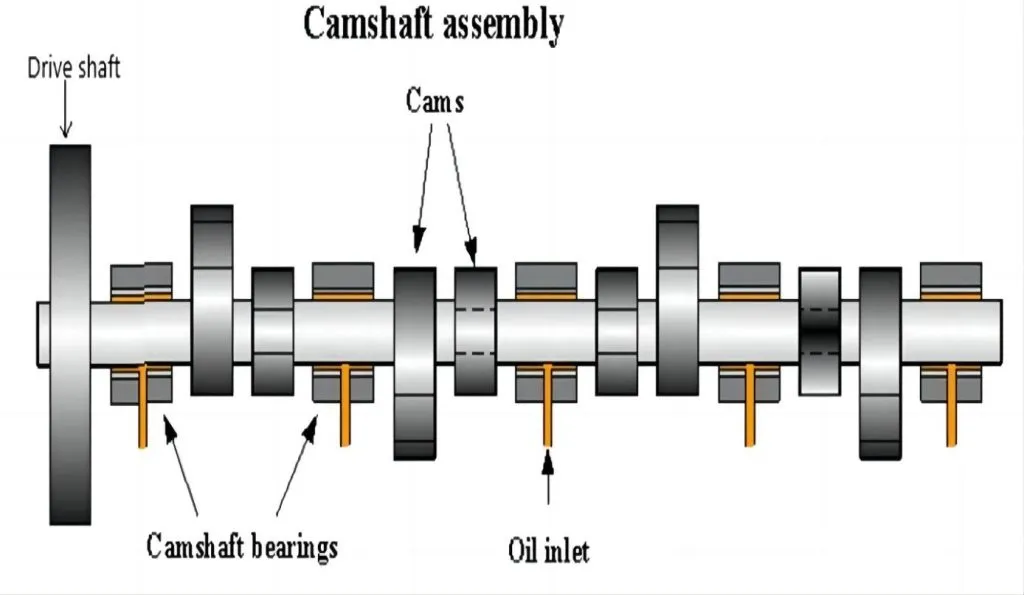

A camshaft is a rotating shaft ready with cam lobes that convert rotational movement into linear motion, controlling the opening and last of consumption and exhaust valves in an engine. This synchronization is essential for green air-gas combination consumption and exhaust fuel expulsion, directly influencing engine efficiency, electricity output, and emissions.

2. Camshaft Design and Materials

Camshafts are usually produced from solid iron or solid metal, selected for his or her sturdiness and put on resistance. The cam lobes are precisely machined to specific profiles, dictating valve carry, length, and timing. Advancements in materials and manufacturing techniques, such as inductive hardening, have better camshaft durability and overall performance.

3. Types of Camshafts

- Single Overhead Camshaft (SOHC): Features one camshaft in keeping with cylinder bank, working both consumption and exhaust valves.

- Double Overhead Camshaft (DOHC): Employs two camshafts per cylinder bank, one after the other controlling consumption and exhaust valves, bearing in mind advanced performance and better engine speeds.

- Cam-in-Block (Pushrod) Camshafts: Located in the engine block, using pushrods to actuate valves, not unusual in older engine designs.

4. Camshaft Timing and Variable Valve Timing (VVT)

Precise camshaft timing is vital for engine performance. Variable Valve Timing (VVT) systems regulate the camshaft role relative to the crankshaft, optimizing valve operation throughout specific engine speeds and hundreds. German manufacturers have developed superior camshaft adjusters, along with vane cellular adjusters, to enhance VVT skills.

5. Camshaft Manufacturing Innovations in Germany

Germany’s automotive enterprise has been at the leading edge of camshaft era, introducing innovations like camshaft assemblies with inner shafts and outer tubes for stepped forward capability.

Additionally, German manufacturers have developed camshafts designed for particular programs, which include the 16v 288° mechanical exhaust camshaft for Volkswagen engines, improving performance characteristics.

6. Camshaft Maintenance and Common Issues

Regular upkeep is essential to make sure camshaft durability. Common troubles include wear of cam lobes, often due to insufficient lubrication, and timing misalignment, that could lead to engine overall performance troubles. Early detection and proper protection are essential to save you vast engine damage.

7. Future Trends in Camshaft Technology

The destiny of camshaft technology is geared in the direction of in addition enhancing engine efficiency and performance. Developments consist of camshaft adjusters with incorporated brake structures for precise control and the use of superior substances and production approaches to reduce weight and growth sturdiness.

Conclusion

The camshaft stays a essential component in inner combustion engines, with ongoing innovations enhancing its capability and performance. Germany’s contributions to camshaft technology hold to play a full-size position in advancing automobile engineering, making sure engines become greater efficient, powerful, and reliable