Design, Function, and Innovations in the Automotive Industry

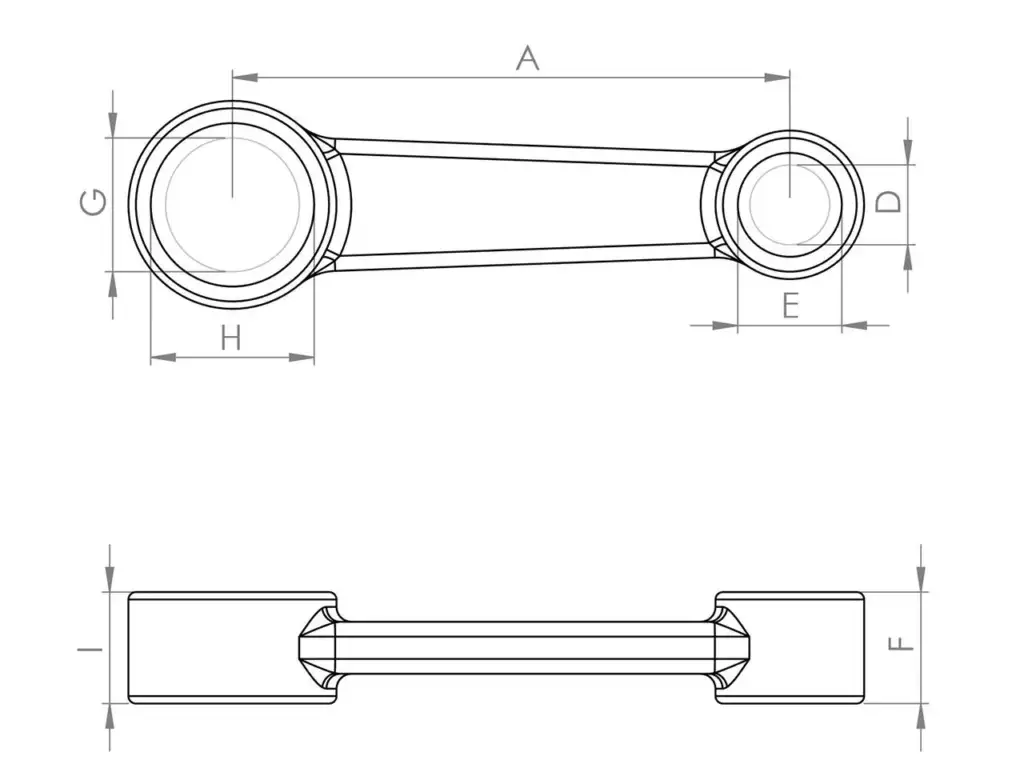

The connecting rod, known as “Pleuel” or “Pleuelstange” in German, is a fundamental issue in internal combustion engines. It serves as the link between the piston and the crankshaft, converting the linear motion of the piston into the rotational movement of the crankshaft. This article explores the layout, function, and latest improvements of connecting rods, with a selected consciousness on traits inside the German automotive enterprise.

1. Introduction to Connecting Rods (Pleuel/Pleuelstange)

The connecting rod is a crucial detail in an engine’s reciprocating assembly. It transmits the pressure generated by the combustion process from the piston to the crankshaft, facilitating the engine’s rotational power. The time period “Pleuel” is typically utilized in German engineering to refer to this element.

2. Design and Materials

Connecting rods are generally crafted from excessive-strength substances which include solid metallic, aluminum alloys, or titanium, selected for his or her sturdiness and capacity to resist the stresses of engine operation. The layout frequently capabilities an H-shaped cross-section, which presents a stability between strength and weight. Advancements in materials technological know-how have led to the improvement of light-weight but robust connecting rods, contributing to advanced engine overall performance and performance.

3. Function and Operation

During engine operation, the piston actions up and down within the cylinder. The connecting rod transfers the linear movement of the piston to the crankshaft, changing it into rotational motion. This method is essential for the continuous operation of the engine, as it allows the crankshaft to rotate and drive the vehicle’s wheels.

4. Manufacturing Innovations in Germany

Germany has been at the forefront of automobile engineering, with widespread advancements in connecting rod manufacturing. Companies like Alfing Montagetechnik specialize in the automation of connecting rod manufacturing, developing specialized loading and unloading systems for transfer lines and rotary table machines.

5. Applications in the Automotive Industry

Connecting rods are crucial to numerous engine sorts, together with the ones utilized in passenger vehicles, business motors, and bikes. For example, the connecting rods for the BMW three Series E90 2.5i are designed to satisfy particular performance requirements, making sure reliability and efficiency.

6. Maintenance and Common Issues

Regular protection of connecting rods is critical to prevent problems including put on, fatigue, and ability failure. Common troubles include bearing wear, bending, and fractures, often as a result of inadequate lubrication or production defects. Implementing proper maintenance practices and using extremely good additives can mitigate these problems.

7. Future Trends and Developments

The future of connecting rod era is centered on improving performance, decreasing weight, and improving gas efficiency. Innovations along with using superior substances, which includes carbon composites and excessive-electricity alloys, are being explored to gain those desires. Additionally, the combination of additive manufacturing strategies holds promise for generating complicated, lightweight designs that have been formerly impossible.

Conclusion

The connecting rod is a essential factor in inner combustion engines, playing a crucial function in the conversion of energy within the engine. Ongoing advancements in design, materials, and manufacturing tactics, specially in the German car enterprise, continue to beautify the performance and performance of connecting rods, contributing to the evolution of modern-day engine generation.